From a husband-and-wife team who wanted to build a culture around Thai chocolate (Nuttaya and Paniti Junhasavasdikul) to a family that wanted to feed their children clean food, (Kathaleeya McIntosh and Songkran Grachangnetara) these artisans have collectively elevated the quality of homegrown products in Thailand.

“When I first arrived in Thailand, most ingredients seen as high quality were imported,” says Joe Sloane, an artisan meat distributor who came to Thailand in 2007 as a chef. It was a slow process, but things are changing.

The Royal Project started receiving support from chefs which began to change perceptions of local produce. “A new breed of independent restaurants started to do something interesting to get noticed,” says Sloane.

One of these restaurants was Bo.lan (One MICHELIN Star), which in 2012 launched a monthly farmers’ market on the grounds of its former Sukhumvit Soi 26 location. This gave farmers and producers a platform, as well as the boost they needed to kick-start the Thai locavore movement.

There’s no doubt this movement has now taken hold. Other than trailblazers Bo.lan, other acclaimed restaurants championing local produce include One MICHELIN Star restaurants J'AIME by Jean-Michel Lorain, Paste, Sorn, Le Du, Saawaan, Canvas and PRU.

The Community

There’s a sense of collaboration in the local artisanal food community today as people work towards the same goal. There’s also an underlying rejection of the mass production of food that defines and unites the community.“It’s a growing market and there’s enough for everyone to share,” says McIntosh, whose Sirin Farm invests in the local community and supports local farmers with egg packing and logistics.

Similarly, Sloane’s supports the farms it works with, assisting with HACCP (Hazard Analysis Critical Control Points) certification and logistics at Tankhun Organic Farm – a cooperative in Nakhon Pathom that’s now selling to a few top restaurants, including Le Du (One MICHELIN Star).

At the production level, family-owned businesses like the organic rice farm in Sisaket, Raitong Organics, are now being run by a new generation who are taking things to the next level. The facility already includes a pig farm that uses permaculture methods. “Currently, production is still small,” says Sloane. “But they hope to encourage other farms in the area to follow the same ethos and set up a co-operative of farmers.”

Right: Sloane's pork terrine.

Cooperative efforts are standard amongst the farms used by homegrown cocoa trader Kad Kakao. One of the suppliers they work with in Chiang Mai was already USDA (US Department of Agriculture) Organic-certified for coffee plants so Kad Kakao’s founders Nuttaya and Paniti Junhasavasdikul – both certified by the Fine Cacao and Chocolate Institute (FCCI) – are now working with the grower to obtain the same organic certification for its cacao.

Kad Kakao currently produces five single-origin chocolates (a sixth is under development), but one of the couple’s long-term plans is to set up a Thai cacao foundation to share knowledge amongst growers and consumers. “We came into this business wanting to change the culture of Thai chocolates,” said Paniti.

The Challenges

Despite positive trends, the challenges facing small-scale producers are still considerable. For years, the perception in Thailand has been that if food is local, then it should be cheap. But when it comes to artisan food products, that’s often not the case.“Farmers are pushed to produce more all the time, and the market puts pressure on the price,” says Laurent Opportune, the owner of Klong Phai Farm in Khao Yai which produces farm pasture-raised poultry free of hormones and antibiotics. Yet the Frenchman is cautiously optimistic. “More and more chefs are seeking out quality ingredients, but the growth is very slow,” he says.

Kathaleeya McIntosh, owner of Sirin Farm, a family-owned organic farm in Chiang Rai, counts herself and her husband as one of few producers who were able to overcome the obstacles that may limit new small-scale farmers. Having started with 1,200 hens three years ago, the farm now raises over 10,000 certified organic hens, 30 sows, and five Berkshire boars (the first and only certified organic pig farm in Thailand) on their 40-rai (6.4-hectare) farm. “Regulations are written for the big boys,” she said. Amongst the hurdles she cites are the requirement from distributors for a continuous supply, account management fees and payment in arrears, all of which prove burdensome to small businesses.

Right: Songkran Grachangnetara with baby Berkshire pigs.

Others point to a lack of support in terms of education and infrastructure. “Despite the fact that Thailand has been growing cacao for over four decades, buyers still lack choice, not just in terms of bean types, but also post-harvest methods and the diversity of cacao offered,” says Natalie Suwanprakorn, who sources beans directly from farmers across Thailand to craft her Xoconat bean-to-bar chocolate and confections. “Standardised fermentation and drying techniques are essential, but this requires government assistance for farmers.”

Seal of Approval

Thanks to proactive work by producers, the perception of homegrown products is changing in Thailand, even when it comes to those traditionally associated with other countries.To overcome the initial apprehension of Thai-produced chocolate in a local market that preferred Japanese and Belgian brands, for example, Kad Kakao’s founders actively sought international recognition. In 2018, their Chiangmai Grand Cru Cacao made international headlines when it won the Bronze Award (Asia Pacific) and was recognised as a Grand Jury Finalist (World) in the International Chocolate Awards 2018 in Italy.

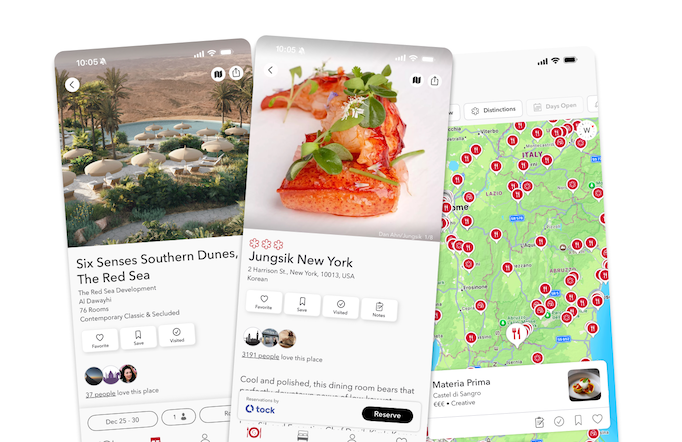

Similarly, the notion that Russian or Iranian caviar is best was challenged when a Bloomberg article published in 2017 pointed out that caviar produced in China was served in 21 of 26 Three MICHELIN Starred restaurants in Paris.

It’s the same Chinese caviar imported by the Caviar House of Bangkok to grow the local market, from 130 kgs in 2016 to 650 kgs in 2018.

“The quality of caviar depends on the feed, water conditions and processing,” said Alexey Tyutin, co-founder of the Caviar House of Bangkok. “So technically speaking, we can produce top quality products anywhere if we maintain the right conditions for the fish, give them a balanced feed, and use the best farming techniques.”

Tyutin is also the managing director of Thai Sturgeon Farm, a sturgeon breeding farm in Hua Hin with a capacity to produce 1.5 tonnes of black caviar annually. In November 2019, Thai black caviar production will start at the aquaculture farm, three years after sturgeon fry (babies) were imported from China.

Whether the growth in the local farming projects is down to the producers or the chefs is something of a chicken-and-egg conundrum.

“The support and endorsement from chefs in the top hotels and restaurants allow small artisan producers to grow,” says Sloane. McIntosh agrees. “It’s the chefs who make our produce into something special and have influence on sharing our story,” she adds.

As a handful of the Thailand’s top chefs will attest to, their stories are worth sharing.